making your glass stronger & safer

providing superior quality, exceptional service and product innovation.

toughening

Annealed glass is made stronger and safer through a process known as toughening. The resulting product – toughened glass – is classified as a Class A safety glass. Unlike annealed glass, if it becomes damaged, or shatters, it does not break into sharp shards which can cause serious injuries.

The toughening process causes the glass to break, instead, into small glass pebbles, most of which will fall harmlessly to the ground. Although it is possible to receive minor abrasions or bruises from a fall of glass pebbles, these smaller fragments do not cause serious injury.

Toughened glass starts out as an ordinary panel of annealed glass. This must be cut to size before treatment, including polishing, drilling any holes or routing any notches or cut outs required. Once the panel is the exact dimensions and specification for the client, it is washed and dried before being treated in a furnace.

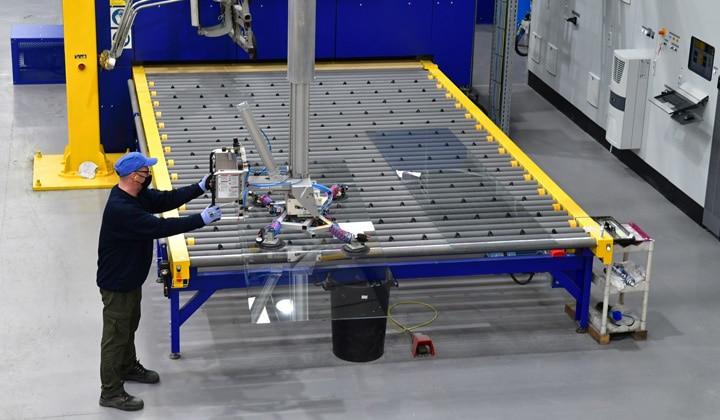

The glass is carried into the furnace on a set of rollers, which keep it moving continuously in what is known in the industry as a ‘roller wave’. The panel is rocked gently backwards and forwards in the heat until it becomes malleable.

Rollers then carry the glass through the second phase of the toughening process, in which is it cooled by blowing cool air onto its surface. This stage is known as a quench. The surface of the glass panel cools more quickly than the centre, creating a sealed tension which changes the panel’s overall integrity. This newly treated panel now has 4 to 5 times the strength of ordinary annealed glass. Thanks to this added strength, the glass can now be used safely in a wide range of applications such as partitions, low-level balustrades, bespoke glass shower screens / enclosures, wall cladding and splashbacks.

The toughening process can create subtle surface distortions which often add to the attractiveness of the glass. Once toughened, the glass is much safer, because it will shatter into small, lightweight fragments rather than shards.

Please note:

We do not rework glass once it has been toughened, as this can cause a weakness and compromise its strength. There is a tension that can be created in toughened glass, due to the presence in annealed glass of nickel sulphide. In annealed glass, this is completely inert, but, in rare occasions, in toughened glass, this inclusion can expand over time and cause the panel to combust. Because the presence of nickel sulphide is due to the annealed glass manufacturing process, we cannot be held responsible for the replacement of a panel in the vary rare possibility that it may shatter.

Although is not a 100% guarantee, the risk of spontaneous breakage can be greatly reduced by subjecting the glass to a further process called heat soaking. If you are planning to use the glass panel in a guarding situation, we strongly recommend that it should be heat soaked.

Like all our manufacturing processes, our toughening process is governed by strict quality standards. All our toughened glass is manufactured in compliance with BS EN 12150. Our entire range is manufactured in accordance with our BS EN ISO 9001:2015 assured quality management system.

heat-soaking

The presence of nickel sulphide in annealed glass can create a potential for a particular flaw in toughened glass, which we do our utmost to guard against. When toughened glass is created, the more rapid cooling of the outer surface can cause an inclusion of nickel sulphide to be encapsulated within the panel.

Although the presence of nickel sulphide in annealed glass poses no threat at all, on very rare occasions, in toughened glass, this inclusion can expand over time and cause the panel to combust. Much of the risk of this can be eliminated by a process known as heat soaking, which we strongly recommend in all guarding situations in which toughen glass is used.

The heat soaking process helps to expose nickel sulphide inclusions in toughened glass. The toughened or heat strengthened glass is placed inside a heat soaking chamber, where the temperature is gradually raised to approximately 290ºC. It is then held at this temperature for two hours. This accelerates the expansion of any nickel sulphide inclusion. If there are nickel sulphide inclusions, the panel is likely to break inside the heat soak chamber. We then know to create a new unaffected panel, which can be installed instead.

As part of the heat soaking process, we replace the panel and repeat the process to fulfil your order. This greatly reduces the risk of a potential spontaneous breakage occurring in-situ.

Please be assured that combustion in glass panels is rare. Without heat soaking, industry guidelines tell us that 1 in every 4 tonnes of glass will be affected by a combustion problem. However, in glass that has been through the heat soaking process, the risk drops significantly, to 1 in every 400 tonnes.

Our heat soak testing is conducted in accordance to BS EN 14179.

Because nickel sulphide is introduced as an inherent property in the float glass manufacturing process, before it reaches us, we cannot be responsible for replacing any glass panel that breaks in situ, or for any costs associated with this very rare occurrence.

As an additional service we also supply heating profile graphs as supporting evidence that the heat soak test has been conducted correctly.

heat strengthened

Heat strengthened glass is similar to toughened glass, as it also goes through the furnace process. The difference, in this instance, is that the cooling process is completed at a much slower pace. This gives the panel additional strength. Although not as strong as toughened glass, heat strengthened glass is approximately twice as strong as untreated annealed glass of the same size and thickness.

Heat strengthening also imbues the glass with enhanced thermal properties, making it an ideal product for roof glazing (when incorporated into a laminated panel of double-glazed unit.)

As heat strengthened glass is a semi-toughened product, it retains the normal properties of ordinary float glass and doesn’t have the surface distortion that is sometimes associated with toughened glass. It is not classed as a safety glass, as it breaks into shards in a similar way to untreated annealed glass.

Our heat strengthened glass is manufactured in accordance with BS EN 1863.